- Home

-

Our food+

- IDLI & DOSA BATTER

- RICE RAVA IDLI BATTER

- Squeeze and Fry Vada Batter

- Homestyle Whole Wheat Paratha

- WHEAT CHAPATI

- MALABAR PAROTA

- WHEAT LACHHA PARATHA

- SOFT & CREAMY PANEER

- White Bread

- Wheat Bread

- Creamy Thick Curd

- Instant Filter Coffee Liquids

- Filter Coffee Bottle

- Instant Coffee Powder

- Butter Stick

- Frozen Fruit Pulp

- Process

- Recipes+

- About us+

- Factory Live

- Join Our Team

- Media

- Contact us

More

More

-

- Home

-

- Our food

- IDLI & DOSA BATTER

- RICE RAVA IDLI BATTER

- Squeeze and Fry Vada Batter

- Homestyle Whole Wheat Paratha

- WHEAT CHAPATI

- MALABAR PAROTA

- WHEAT LACHHA PARATHA

- SOFT & CREAMY PANEER

- White Bread

- Wheat Bread

- Creamy Thick Curd

- Instant Filter Coffee Liquids

- Filter Coffee Bottle

- Instant Coffee Powder

- Butter Stick

- Frozen Fruit Pulp

- Process

-

- Recipes

- Recipes

- Joy of cooking

- Factory Live

- Join Our Team

- Media

- Contact us

More

More

A PEEK INTO OUR KITCHEN

From the fields till it reaches your table, we make sure everything we make and every step of the process follows two rules - keep it safe and keep it preservative-free. Here’s a little glimpse into how we make our idli and dosa batter that millions enjoy every day. The same hygienic process and care goes into making all our products. We wouldn’t do anything less when we serve our families and yours.

Explore

THE NOT-SO-SECRET INGREDIENTS

The best quality of rice, urad dal, and methi is sourced and stored in a clean and dry warehouse. The ingredients are then lifted into the manufacturing unit.

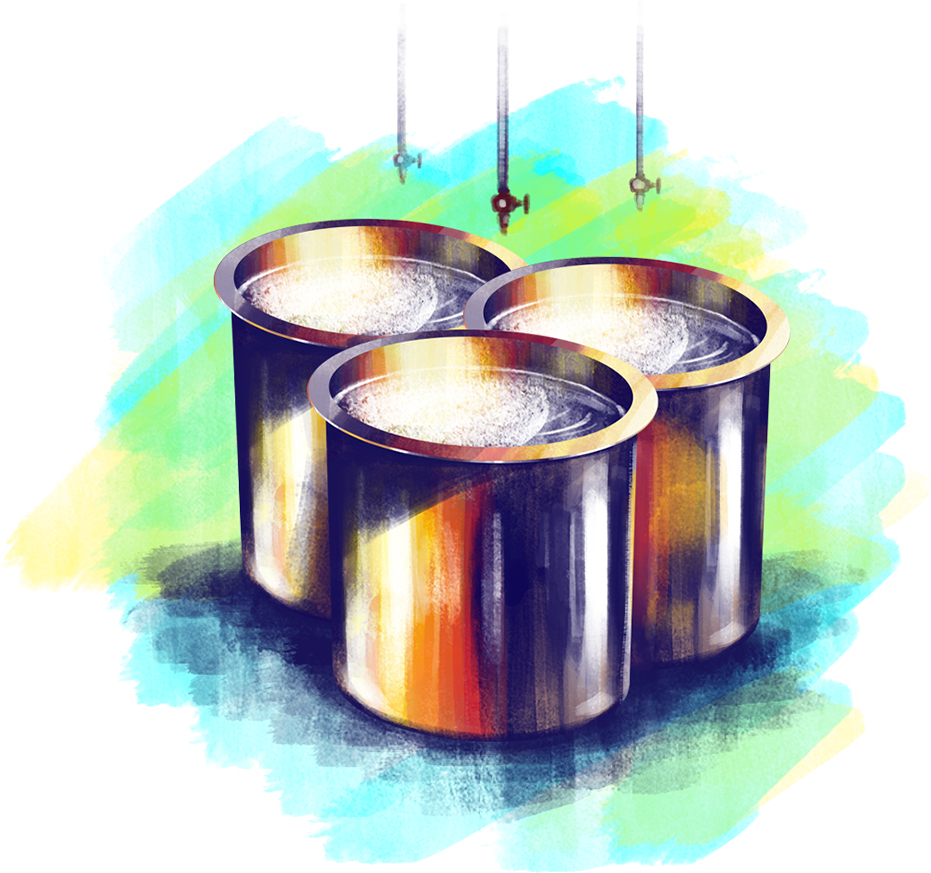

SOAKING IN IT

The softest idlies are made from ingredients that are allowed to take their time to absorb just the right amount of water.

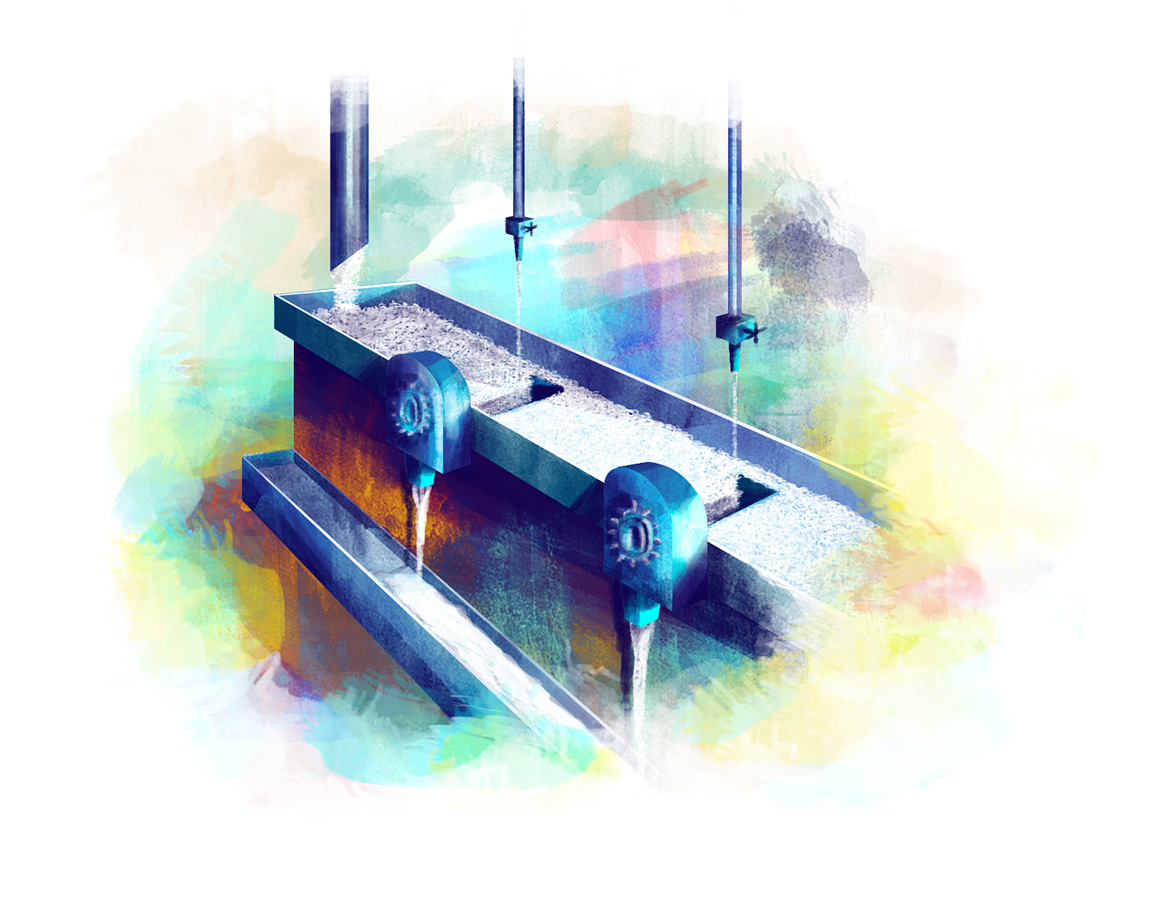

THE DAILY GRIND

Under close watch, the grains and pulses are separately ground to a specific consistency with a dash of salt.

THE PERFECT MIX

The finely ground rice, urad dal, and methi are now combined.

RISE AND SHINE

There is no shortcut to silky smooth batter. Fermentation to right degree is key.

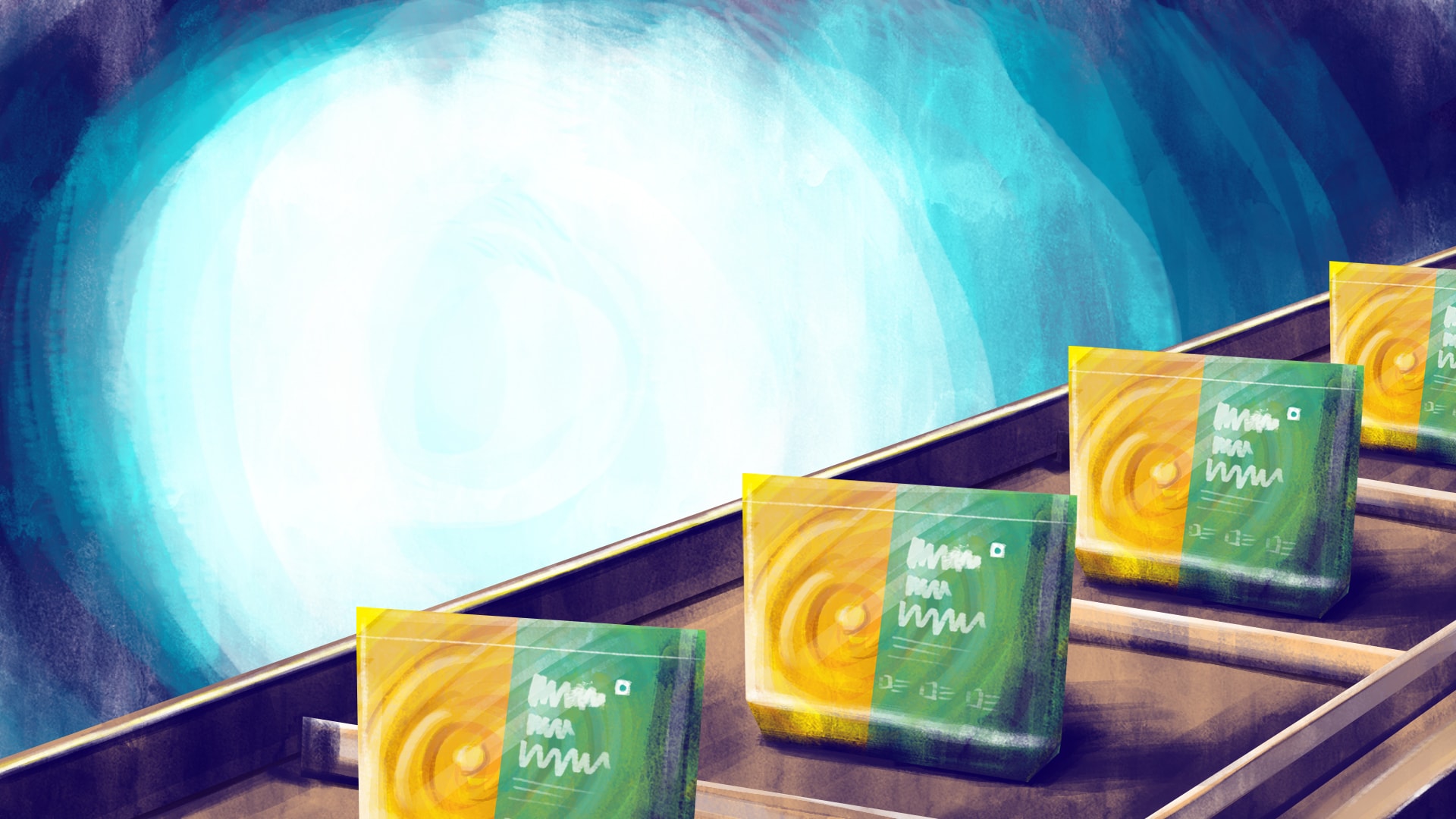

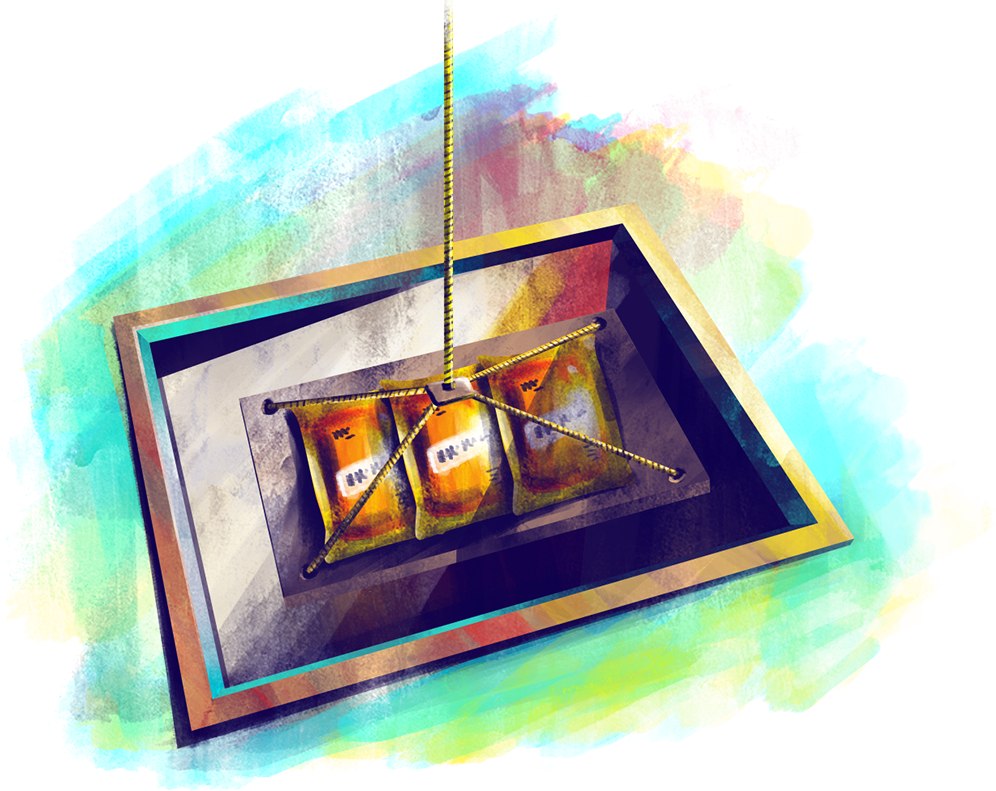

SIGNED, SEALED, AND SOON TO BE DELIVERED

The packs are filled, weighed, air-sealed and sent through a metal detector to ensure there is no adulteration before they are sent to the blast freezer.

NOW READY TO BE SERVED WITH LOVE AND CHUTNEY

The batter then travels to retailers near you. When you pick-up a packet of iD batter, you choose food made with love.

- Locations:

- India

- UAE

- UK

- USA

- Saudi

- Oman

- Qatar

Designed by Langoor